Mold manufacturing process

-

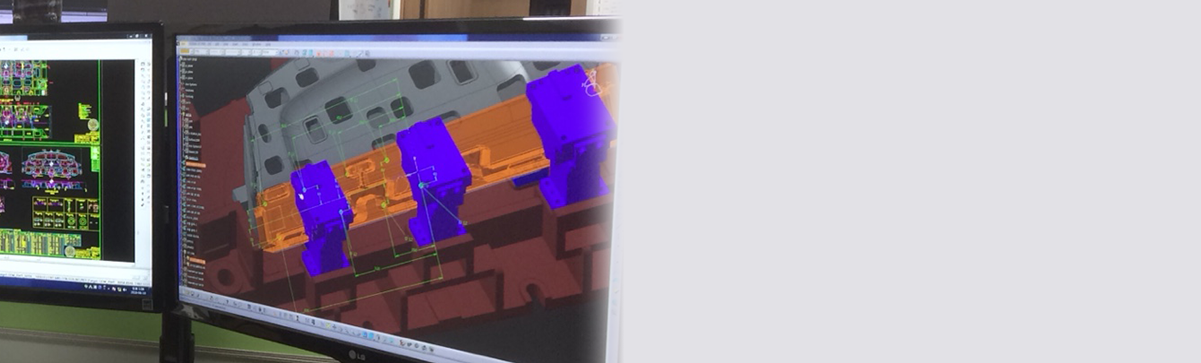

Step 1 Review customer's CAD DATA

Feasibility study for mold structure and formability Submit an estimate, dilivery schedule

-

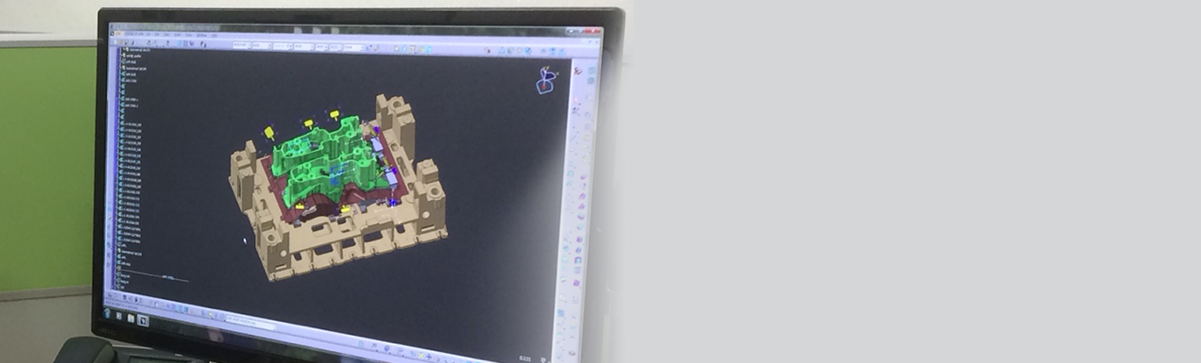

Step 2 Design Pattern CATIA DATA

Design a pattern CATIA DATA based on the internal manufacturing standard and customer requirments

-

Step 3 Pattern manufacturing

Make an evaporative-pattern using polystryrene form by NC machining

-

Step 4 CNC machining DATA and 3D Modeling DATA

Make CNC machining DATA and design 3D modeling DATA

-

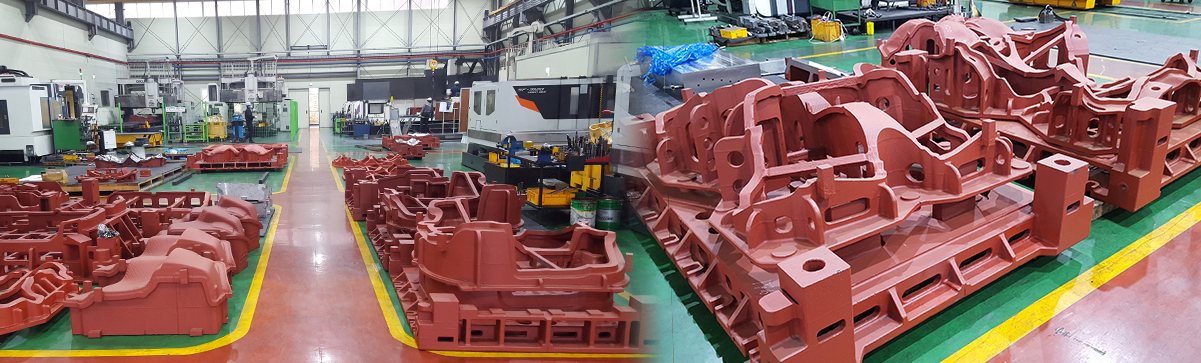

Step 5 FC or AL casting for mold body

Make FC or Aluminium mold body by Full Mold Casting method using pre-NC machined polystyrene form pattern (The pattern is coated with a refractory material. The coated pattern is then placed in a flask and packed carefully with green sand or a chemically bonded sand. Finally, the molten metal is poured into the mold, which vaporized the foam allowing the metal to fill the entire mold. The casting is allowed to cool and then dumped out of the flask ready to use)

-

Step 6 CNC work

Machine the surface of FC or AL casted mold using WORK NC program on 3D CNC machine

(Rough→Semi-Finishing→Finishing machining) -

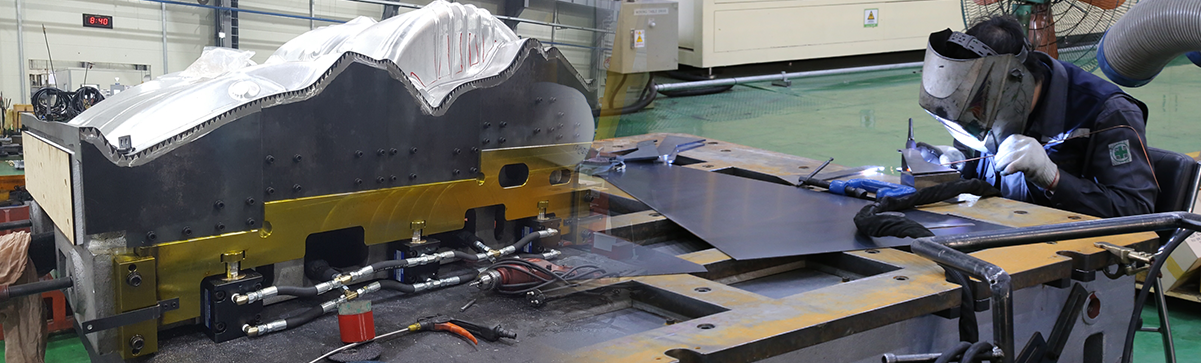

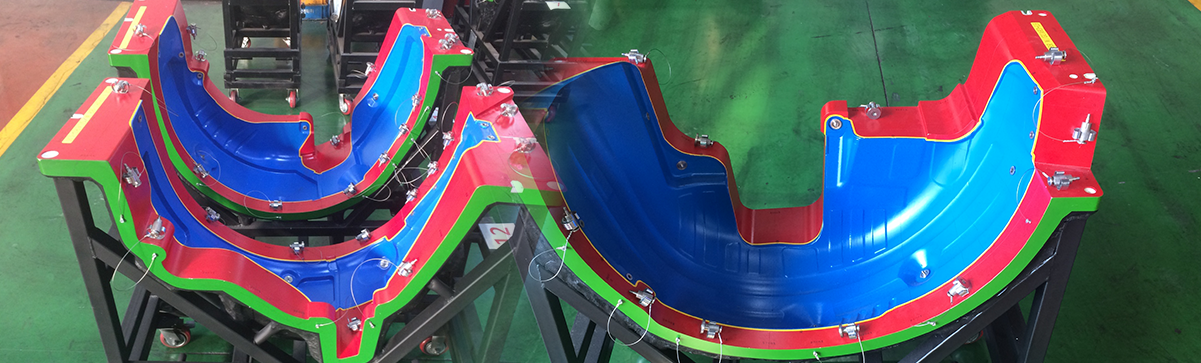

Step 7 Finishing & Assembly

Assemble all the related parts in accordance with the drawings

-

Step 8 Die spoting

Combine the upper & lower mold on the hydaulic press machine for checking contact surface

-

Step 9 Try-out

Try out the finished mold for making products and check all the parts on mold

(1st Try-out in-house and 2nd Try-out in a customer's factory) -

Step 10 Dimension inspection

Mount the finished product on the checking fixture and check dimension in accordance with approval drawings.